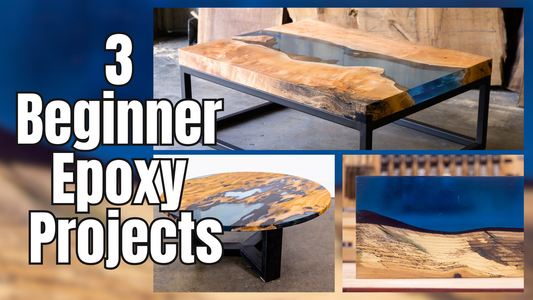

I Try Viral Epoxy Countertop Products

You guys have been asking if I could try an epoxy countertop, and Stone Coat Countertops sent me an entire kit, so this week we’re giving it a shot. If you guys remember on our three-level cabinet build, I built a cherry cabinent and didn’t do a top for it because I planned on getting a piece of stone. But that’s expensive, so to get the same look as stone, we’re going to try out epoxy countertops. The epoxy kit from Stone Coat Countertops is supposed to be easy to work with, affordable, and adaptable to most substrates. You’ll have to watch the full video to see how this project turned out.

Making Our Own Countertop Out of Epoxy

The team walks through the steps of how to make an epoxy countertop

To get this project started, we grabbed a piece of leftover MDF. We cut it to size and prepped it to get started. First up, we used the top coat sent to us, which called to roll on two coats. After that dried, we got started mixing our epoxy. For this project we used Stone Coat Countertops’ art coat. After mixing, we segmented our resin mixture to add pigment. We put on a base coat of resin and then added in the resin with pigmentation. After a few finishing touches, we let this bad boy sit overnight to dry. In the morning, we sanded off any unwanted resin on the bottom. Make sure you watch the full video to see how this project turned out.

Tools and Materials

All the tools you need to make your own epoxy countertops

To get us started on this project, we used a piece of scrapped MDF and cut it with a table saw to fit the dimensions of the cherry cabinent. Using our Woodpecker’s corner jig, we rounded out the sides. To finish this out, we used a sander to get rid of any saw marks.

With the epoxy, we used a scraper with the initial coat of resin to even everything out on the board. Using a paint brush, we eliminated any streaks by using a chopping motion with the brush on the epoxy, and with that same motion, we added in the pigmented epoxy to the board in a way that mimicked marble. With a heat gun, you can move the resin around to perfect the look of what you’re going for. To finish it out, use a blow torch to get rid of any bubbles in the epoxy.

After this dried, we used a sander with 80-grit to remove any left over epoxy from the bottom. Not per Stone Coat Countertop’s recommendation, we sanded the resin with a 220-grit to give it more of a matte finish. After wiping the piece down with denatured alcohol, we used Rubio Monocoat as a finish to seal everything up.

Top Tools and Product Affiliates

Check out some of my top tools and product affiliates here.

Extra Supplies

Check out some of my merchandise, build plans, and go-to safety glasses.

- Plans

Thanks for watching and supporting me! If you liked this project, be sure to check out my merch and other projects here: